For your heavy duty playgrounds

03.03. – 07.03. 2026

We will be back at Conexpo/IFPE in Las Vegas, USA. Visit us at our stand S84107 in South Hall 3-4, we look forward to inspiring discussions with you!

NEXT-GENERATION DRIVES

NAF AG is a global leader for bogie axles, with a payload range of 10-50 metric tons and optional patented solutions, such as the company’s Permanent Bogie Balancing System for rough terrain and the harshest conditions.

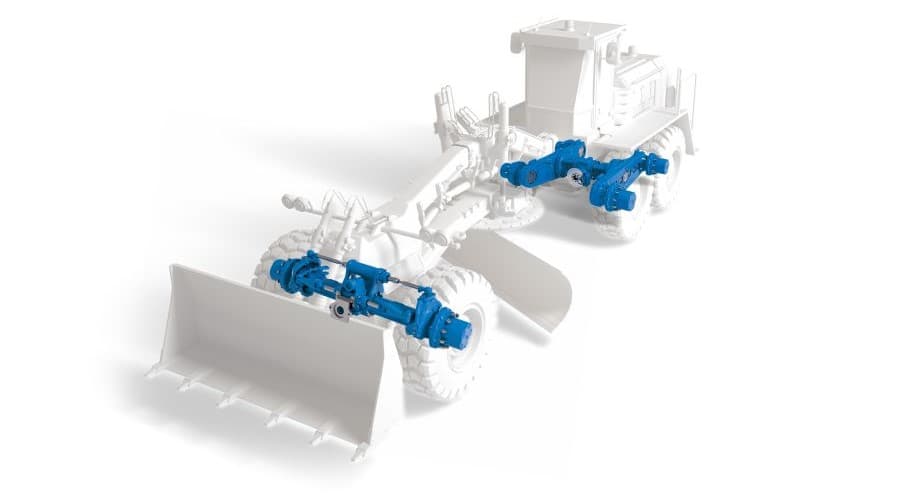

The NAF product portfolio features steering, rigid and bogie axles, as well as gearboxes for applications in forestry, agriculture, mining, material handling, construction, airport and off-road heavy-duty transport. With NAF’s modular system, it is possible to combine technical features, such as a planetary gear drive with a patented turbo brake, as well as a multiple disc differential lock for perfect traction control.

Industrial solutions

In the construction sector, NAF specializes in drive solutions for articulated dump trucks of up to 45

metric tons and motor graders with up to 350hp.

Due to its long-term experience with bogie axles and wide range of suitable components, NAF is open

to customized solutions.

NAF’s modular designs allow it to offer the cost advantages of a standardized product line, but with a high degree of fl exibility and faster project completions.

NAF focuses on strong and reliable drive solutions for heavy motor graders. For applications with a

top-to-rear bogie axle, NAF supplies an all-wheel drive with a directly driven front axle, including

a side tilting and two-motor gearbox for a full hydrostatic system.

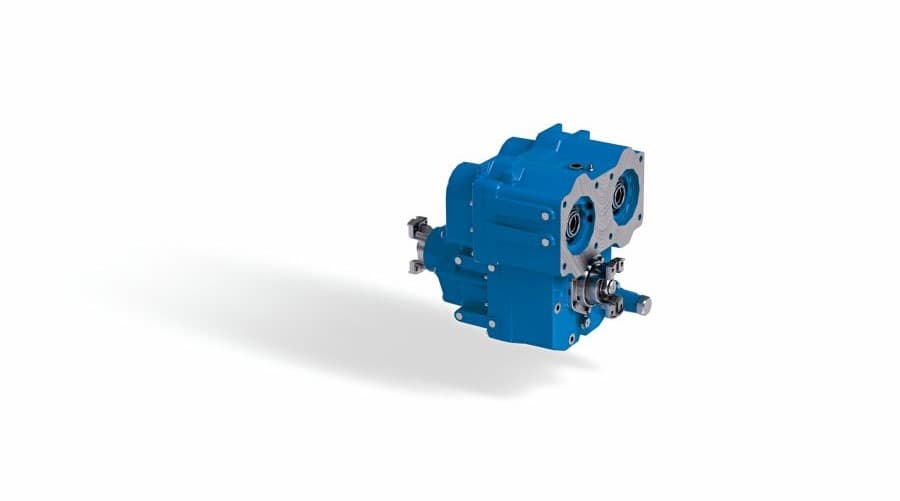

Multifunction gearbox

The patented DualSync gearbox can provide hydrostatic continuously variable transmission (CVT) functionality for the entire speed range. The configuration allows two operating modes:

simultaneous use of both motors for high tractive effort and perfect control at low speed; and fuel

saving, single-motor mode for high driving speeds.

Both motors that drive NAF’s mechanical DualSync gearbox are connected with different ratios. When the second motor (with the higher ratio) reaches its speed limit, it is declutched by a synchronizer ring and the fi rst motor takes over up to maximum speed. When reducing speed, the second motor is smoothly clutched in again by the synchronizer to reach maximum tractive effort at low speed.

This system combines perfect functionality with a high tractive effort, robust and trackproven design, fuel savings of up to 20%, as well as improved machine control compared with torque converter systems. In addition the diesel engine is mainly driven in its most effi cient speed range.

The system ensures smooth upshift and downshift without jerky interruptions. Different ratios and

hydro motor sizes are available for combination with the gearbox to cover different machine sizes

and applications.

Source: IVT International, March 2018

For your heavy duty playgrounds

03.03. – 07.03. 2026

We will be back at Conexpo/IFPE in Las Vegas, USA. Visit us at our stand S84107 in South Hall 3-4, we look forward to inspiring discussions with you!

We use cookies on our website. Below you can choose whether and if so, which non-essential cookies you wish to accept and receive further information on this.